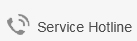

Automatic plastic injection blowing ...

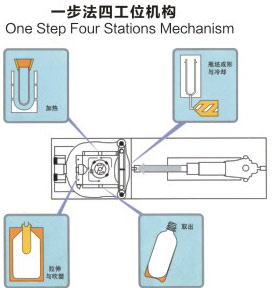

One step forming machine pioneer, flexible and efficient 4 station process.

The one-step forming machine for preserving the preform in the forming process of heat can be effectively used, so the total energy use in the whole process of the 2 step is much lower, forming a high degree of freedom, the most suitable material container outside the special shape as well as PET, PC, PP forming, can produce high quality bottle.

JG-SFF-120 A small container (medicine dropper, test a small container special)

| Name | Unit | Data |

| Screw diameter | mm | 30 |

| Theoretical injection volume | g | 128 |

| Injection mould locking force | kn | 120 |

| Suitable raw materials | kn | 30 |

| Motor power | kw | 11 |

| Heater power | kw | 5.8/4 |

| Working pressure | mpa | 0.7-0.9 |

| blowing pressure | mpa | 2-3 |

| Cooling water | bar | 1-3 |

| Machine size | cm | 300x128x285 |

| Machine weight | kg | 3000 |

| Suitable raw materials | PET PP | |

JG-SFF-210 Cosmetics, health care products

| Name | Unit | Data |

| Screw diameter | mm | 35-40 |

| Theoretical injection volume | g | 184-220 |

| Injection locking force | kn | 210 |

| Blow mould clamping force | kn | 80 |

| Motor power | kw | 18.5-20 |

| Heater power | kw | 6.4/4.7 |

| Working pressure | mpa | 0.7-0.9 |

| lowing pressure | mpa | 2-3 |

| Cooling water | bar | 1-3 |

| Machine size | cm | 330x128x285 |

| Machine weight | kg | 3100 |

| Suitable raw materials | PET PP Tritan | |

JG-SFF-350 Milk bottle, food用

| Name | Unit | Data |

| Screw diameter | mm | 40-48 |

| Theoretical injection volume | g | 220-410 |

| Injection locking force | kn | 350 |

| Blow mould clamping force | kn | 80 |

| Motor power | kw | 22 |

| Heater power | kw | 9.4/4 |

| Working pressure | mpa | 0.7-0.9 |

| Blowing pressure | mpa | 2-3 |

| Cooling water | bar | 1-3 |

| Machine size | cm | 380x140x285 |

| Machine weight | kg | 4000 |

| Suitable raw materials | PET PP Tritan | |

JG-SFF-500 5 gallon PC barrel special

| Name | Unit | Data |

| Screw diameter | mm | 70-75 |

| Theoretical injection volume | g | 1060-1500 |

| Injection locking force | kn | 500 |

| Blow mould clamping force | kn | 300 |

| Motor power | kw | 55-75 |

| Heater power | kw | 18/4 |

| Working pressure | mpa | 0.7-0.9 |

| Blowing pressure | mpa | 2-3 |

| Cooling water | bar | 1-3 |

| Machine size | cm | 710x230x500 |

| Machine weight | kg | 13800 |

| Suitable raw materials | PET PP | |